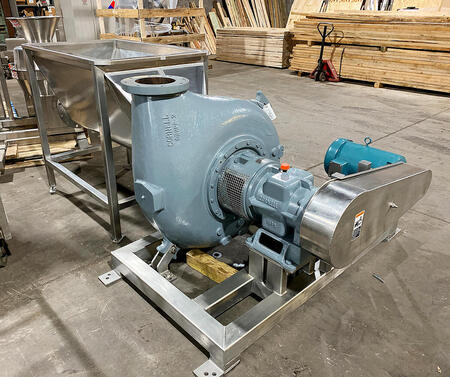

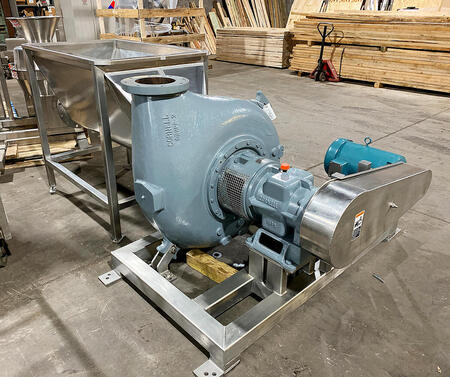

8-inch HYDRO TRANSPORT FOOD PUMP

with STAINLESS STEEL VORTEX TANK and MOTOR-DRIVE...

Food grade pump-in-water conveyor / flume kit including Cornell 8-inch food pump, integrated with a CMI feed tank, and motor-drive. Pump whole or cut food products via pipe flume or open sluice, to cool, wash, rinse, sanitize, and/or apply preservative solutions while conveying horizontally and/or vertically for long or short distances.

Ideal for food processing applications such as fruit and vegetable washing, fresh-cut / pre-cut produce hydro-cooling and chilling applications, and/or pre-heating prior to cutting, peeling, etc; including shredded lettuce and cabbage, cut romaine, whole or cut potatoes, french fries, potato chips, live fish (!), cranberries, carrots, apples, cherries, peas, broccoli, crayfish, shrimp, lettuce, green beans, nuts, peppers, olives, cucumbers, raisins, beans, corn, peaches, beets, oranges, and more.

FEATURES:

- Cornell 8NHPP-F18K cast-iron hydro flow food pump with eight-inch inlet and outlet. Stainless steel body pump also available; --call 315-589-4511 do discuss your specific requirements.

- Manufacturer rated for solids handling ability for product sized up to 5 inch diameter by 9 inches in length. Larger diameter pumps are available for larger product sizes; --call 315-589-4511 do discuss your specific application requirements.

- Expanded volute PP series pump for the ultimate in gentle handling of delicate food products. So gentle the manufacturer rates for pumping live fish!

- Specifically designed and built for industrial food processing application use, with tons-per-hour throughput capacity.

- Manufacturer recommends 2 or 3 to 1 ratio of water to product, with your product capacity determined by horsepower, RPM, and total dynamic head resistance. Pump curves are available by request; --call 315-589-4511 do discuss your specific application requirements.

- CMI stainless steel in-feed tank 48 inches long by 29.5 inches wide by 28 inches deep with a tapered bottom.

- The tank has a 2.5 inch inner diameter NPT threaded end cleanout drain near the discharge flange end, with a valve.

- The pump, tank and drive, are integrated, with pump and motor drive on a heavy 4 inch square tubular stainiless steel frame.

- 7.5 HP 208/230/460 volt 3 phase belt and pulley drive.

- Previously used as a cooling flume feed pump and configured as we received it; but if you have need for a different configuration, we are dealers for Cornell, and can offer NEW equipment configured to your exact specification; --CALL 315-589-4511 to discuss your precise requirement.

The Cornell hydro transport food pump is frequently employed to power open water flume systems, while others, pump into a closed pipe flume, which they run in a coil pattern on the ceiling to conserve floor space. The flumes provide hold time to remove heat, and extend exposure to the water, which usually includes either a sanitizing agent, or a preservative solution such as vitamin C; depending on the product. The power of the Cornell Hydro-Transport pump allows food producers to deliver their now chilled and treated ingredients to any point in the plant where they want to dry, mix and pack the final product.

Others use the chill flume for pre-cooling blanched (very lightly cooked to kill the active enzymes) food products in water prior to running them through an IQF freeze tunnel. Others use the cooling flume system just to convey product in water.

In every case, the powerful Cornell pump can gently move high tons-per-hour output to wherever it needs to go in the plant.

Alard also stocks and handles various kinds of dewatering, solids-separation, water recovery and filtration equipment to recover the food product from the pump water, and to recapture, treat and recirculate the water as necessary, as well as drying and packaging equipment to complete the process; all tailored to the end-user's specific food product(s) and application.

With Cornell's large range of hydro-transport pump size and material configurations, and with Alard's ability to configure and "gear" the pump to the buyer's specific needs, Alard's Cornell Hydro-Transport based flume kits are a superb tool for a wide variety of industrial food processing applications.

As of this writing, this Cornell food pump flume kit in in stock at Alard, in EXCELLENT operational, mechanical, and cosmetic condition, available for immediate shipment.

CALL 315-589-4511 to confirm availability, and to discuss your particular hydro food pump application requirements.

Alard item reference #:Y4324

1/16 inch drum screen perforations.

1/16 inch drum screen perforations. Standalone stainless steel control panel with touch screen operator control, including variable speed controls for both each drive, and a chart recorder.

Standalone stainless steel control panel with touch screen operator control, including variable speed controls for both each drive, and a chart recorder.